FMC Smoothing the Way to Great Ice

As part of FMC’s ongoing building and equipment renewal program, every year we purchase two new ice resurfacing machines and ice edgers to continually update our fleet for reliability and to incorporate new features and technology to improve ice quality and reliability.

This year FMC operated ice rinks in Revere and Fitchburg are taking delivery of shiny new technologically advanced resurfacing equipment manufactured by the Zamboni Company in Paramount, California at a cost of just under $200,000 per machine.

Although the name Zamboni has become synonymous with ice resurfacing machines, there are actually multiple manufacturers of this type of equipment across the globe. However, Frank J. Zamboni was the pioneer who invented the motorized ice resurfacing equipment that has become absolutely essential to the ice sports industry. FMC uses Zamboni equipment exclusively in all our facilities, not only because of its history and leadership in the ice rink industry, but because the quality and reliability of their machines is unsurpassed.

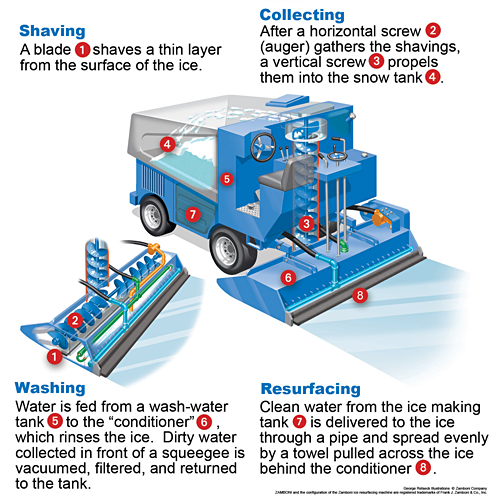

For anyone not familiar with the process of ice resurfacing, the 10-minute ritual that takes place typically every hour in community ice rinks consists of shaving the surface smooth with an industrial shaving blade mounted inside the “conditioner“ as it glides along the ice, collecting the ice shavings through a conveyor system that moves them from the conditioner to the holding tank that sits atop the machine, washing the ice surface to remove debris and fill deep gouges, finished finally with a coating of treated water spread over the surface to provide a smooth glossy finish that is ideal for ice-skating and puck movement.

The new machines that FMC purchases are equipped with many features and upgrades to improve their performance and reliability. These include:

- Lithium Ion battery with intelligent charging system and alternating current (AC) drive system to power the machine reliably and without dangerous exhaust fumes. The battery powered system provides ongoing charging capability without the safety concerns and charging fumes generated by traditional lead-acid batteries.

- On board electronic monitoring and diagnostic system with displays for the operator as well as online data and component status to ensure proactive maintenance that minimizes mechanical failures and skater inconvenience.

- Wash water system with poly tank and strainer / filter system to ensure clean and clear ice that won’t dull skate blades and helps to maintain clear lines and marking on the ice.

- Integral tire wash system to clean any dirt or debris off tires before the machines enters the ice.

- Actuated rotating board brush to clean and remove snow that collects at the intersect of the Ice and dasher boards where the conditioner cannot reach.

- Galvanize coated conditioner with stainless steel water distribution piping to prevent corrosion and resulting degraded performance.

- Integrated conveyor washout system to melt and remove ice shavings from the conveyors to ensure proper collection of shavings from the ice surface into the collection tank.

- Blade changing assistant that allows the rink staff to quickly and safety change the shaving blade (typically twice a week).

Along with the new Zamboni electric resurfacers, FMC purchases Zamboni EZIII battery-powered ice edger machines to keep all dangerous resurfacer exhaust fumes out of the ice rink, ensuring the health and safety of our rink team and patrons. These machines are typically used at least once a day to shave down the ice build-up that occurs at the dasher boards where the ice shaving blade cannot reach.

The continually advancing technology and engineering improvements make the newest generation of Zamboni ice resurfacers the most reliable and best performing in our fleet.

FMC continues our dedication to providing our patrons the best quality skating experience possible with continued investments in not only ice resurfacing equipment, but also in ice refrigeration systems, dehumidification and water treatment.